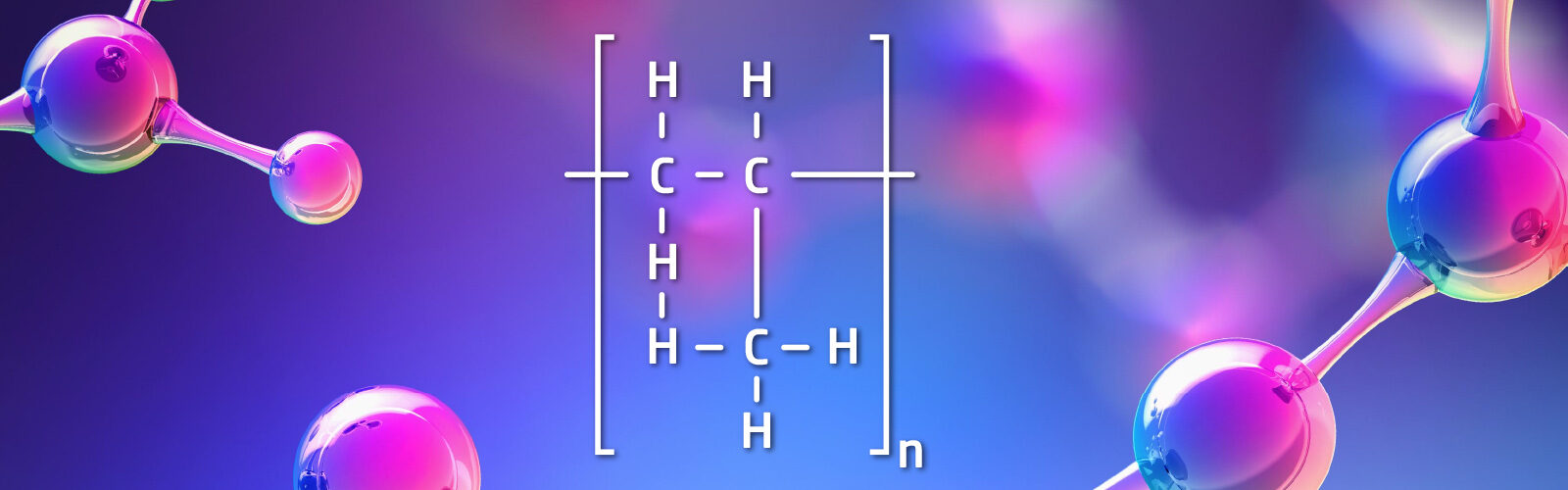

PP (Polypropylene)

PP (polypropylene), also known as polypropene, is a thermoplastic polymer. PP is highly resistant to chemicals. Polypropylene is a widely used type of plastic in plastic equipment manufacturing and plastic piping systems. Polypropylene is not UV resistant. The density of polypropylene is 0.92 g/cm³, allowing it to float on water. Additionally, polypropylene has high heat resistance, is relatively hard, strong, stiff, and tough. Lastly, polypropylene is environmentally friendly, as it is a fully recyclable type of plastic.

Types of polypropylene

PP-H (polypropylene homopolymer)

PP-H exhibits high chemical resistance at elevated temperatures. This makes PP-H particularly suitable as a material for piping systems used to transport various types of media. Consequently, PP-H is widely used as a material for piping systems and sheet materials in water treatment, the chemical industry, and electroplating. The temperature application range of PP-H is from 0°C to +100°C.

PP-B (polypropylene block copolymer)

PP-B is suitable for applications at low temperatures. The temperature application range of PP-B is -30°C to 80°C. This makes PP-B less brittle at lower temperatures due to the chemical addition of ethylene.

PP-N (polypropylene-natural)

PP-N is also suitable for high-quality demineralized water applications due to its low leach-out values. Additionally, PP-N can be joined using the WNF technique, similar to PVDF.

PPs (polypropylene schwerentflammbar/self-extinguishing)

PPs is widely used in electrical engineering and ventilation systems. As the name implies, PPs is a polypropylene with self-extinguishing properties. Additionally, PPs has a high molecular weight.

PP-SK (polypropylene polyester laminated)

PP-SK refers to sheet materials used for liner applications. These sheets are coated on one side with a polyester fiber mat, which simplifies adhesion for lamination.

PP-GK (polypropylene fiberglass laminated)

PP-GK also pertains to sheet materials used for liner applications. These sheets are coated on one side with a fiberglass mat, which simplifies adhesion for lamination. The fiberglass provides better resistance to heat and chemicals compared to other materials.

PP-EL (polypropylene electrically conductive)

PP-EL contains a high percentage of carbon black, making the material electrically conductive. It is highly suitable for ATEX environments. Profilplast supplies sheet materials for this purpose.

Product Range of Profilplast in PP

Polypropylene is a widely used material, especially in industrial piping systems. PP sheet material is commonly used for constructing tanks, dosing cabinets, and other structural components in the chemical industry and electroplating..

Profilplast supplies all components needed for PP piping systems and offers an extensive range of PP sheet materials.

Profilplast holds various certifications in the field of PP, including those from the Bundesgesundheitsambt (German Federal Health Office) and the Food and Drug Administration (FDA).